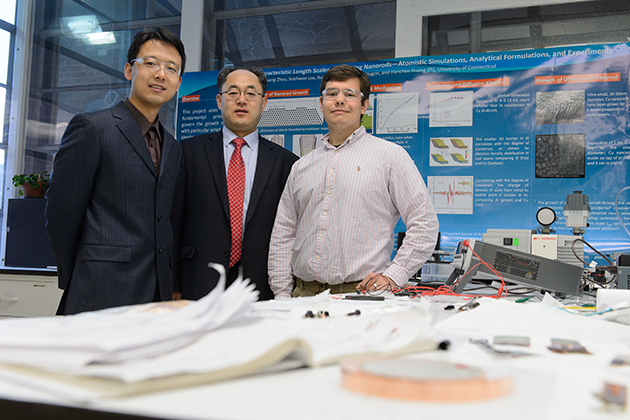

Two graduate-level researchers in the School of Engineering have grown some of the world’s smallest metallic nanorods; a significant scientific breakthrough that their faculty advisor says is a testament to UConn’s robust graduate education programs.

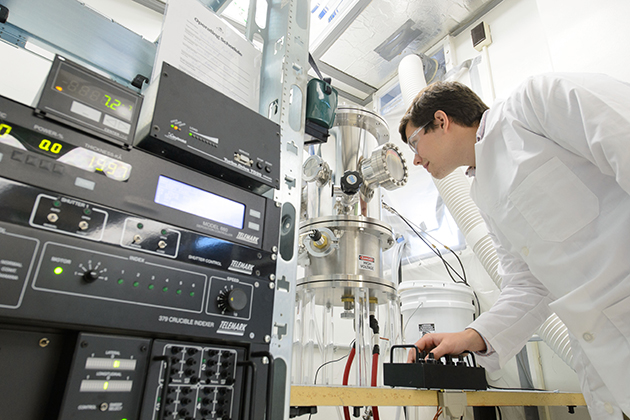

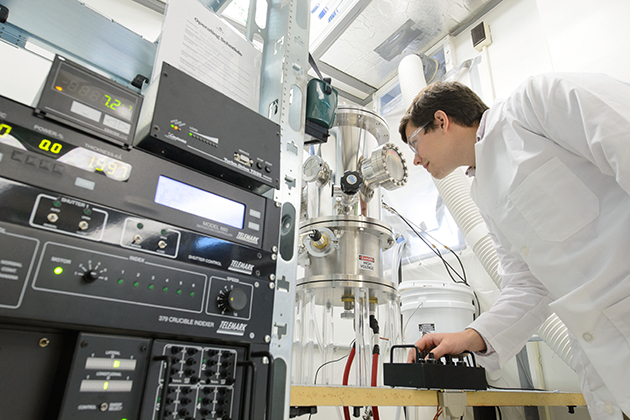

Working under the guidance of Professor Hanchen Huang, postdoctoral researcher Xiaobin Niu and Ph.D. candidate Stephen Stagon broke new ground when they developed the theoretical framework for metallic nanorod growth using a process known as physical vapor deposition.

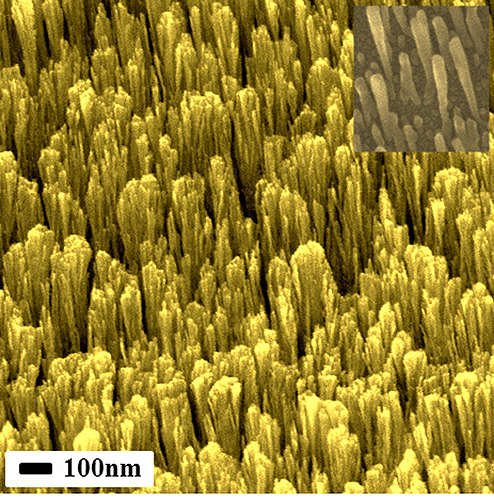

The researchers then used that knowledge to successfully grow noble-metal nanorods 10 nanometers in diameter, which are the smallest ever recorded using physical vapor deposition. The findings were recently published in Physical Review Letters, the world’s foremost physics journal.

“This really opens the door for a multitude of technologies,” says Huang, UConn’s Connecticut Clean Energy Fund Professor in Sustainable Energy and the study’s senior author. “Without the theoretical framework, we would not have been able to make these small nanorods because we had no scientific guidance. This knowledge should have a major technological impact in electronics, energy, and manufacturing.”

Noble-metal nanorods – nanorods made from metals that are resistant to corrosion and oxidation – can be used in microelectronics, powering everything from solar cells to cell phones. Previously, the minimum diameter of metallic nanorods was theoretically unknown, so there was no clear target for experiments and no insight on how to approach the target. While some researchers have grown metallic nanorods less than 50 nanometers in diameter, their success was largely based on chance, observation, and anecdotal evidence. There was trouble reliably duplicating the process for different materials, and the rods often fused together and became a film when their diameters shrunk near the 10 nanometer range.

Developing a closed-form theory for metallic nanorod growth is the culmination of 10 years of work for Huang, who has been continuously supported by research grants from the U.S. Department of Energy’s Office of Basic Energy Sciences Core program. The renewable grants are designed to support fundamental research that helps scientists better understand, predict, and ultimately control matter and energy at the electronic, atomic, and molecular levels.

Niu spent more than a year pinning down the scientific properties of the nanorods’ growth through mathematical formulation and computational modeling, carefully layering atoms upon atoms to see which process worked best. Stagon, meanwhile, carried out accompanying validation experiments at UConn, as well as at the Center for Integrated Nanotechnologies at the Los Alamos National Laboratory.

A key moment came when the team discovered that a long-held classical theory for nanorod growth was flawed. The theory held that only single-layer surface steps were stable, and multiple layer surface steps were not, leading to the impossibility of extremely small nanorod growth within the previous theory. But Huang, Niu, and Stagon found just the opposite, that multilayer surface steps are kinetically stable, and they dictate how subsequent layers of adatoms position themselves – a key development for producing noble-metal nanorods 10 nanometers in diameter or less.

By altering other growth conditions such as the type of substrate, the deposition angle, and the temperature used in the process, the research team was able to successfully grow nanorods that were approximately 10 nanometers in diameter and clearly separated from each other, another important trait that helps enable their performance.

“When you produce metallic nanorods 10 nanometers in diameter or less, nanoeffects take over and you begin to take advantage of those nanoscale properties that everyone is writing about and talking about,” says Stagon, a Connecticut native who was one of the top students in his UConn Mechanical Engineering class when he graduated in 2009. Stagon is also the recipient of a prestigious federal Graduate Assistance in Areas of National Need (GAANN) fellowship, which partially supported his nanorod research.

Smaller is always better when it comes to metallic nanorods, Huang says. Noble metals undergo fundamental changes at the 10 nanometer diameter scale.

“When we think of gold, we see that its color is gold,” Huang says. “But when you go below 10 nanometers in diameter, you start to see purple gold, blue gold, green gold, and all kinds of colors. When you go below 10 nanometers, the element also becomes chemically reactive. Its properties change. You can start to control its electrical conductivity.”

Having nanorods that are clearly separated is also key, Huang says. When the rods are tightly meshed together, it is difficult to add something to them individually. But if they are well separated, you can put a ring or a coating on them, further enhancing their properties and potential.

“This was something that was not possible before,” Huang says. “With the discovery, our colleagues can now coat cheaper nanorods with a very expensive catalyst for such things as advanced fuel cell technologies. This is very exciting.”

Max G. Lagally, Erwin W. Mueller professor and Bascom professor of surface science at the University of Wisconsin-Madison, says Huang’s work with metallic nanostructures has advanced researchers’ understanding of the growth process.

“Hanchen has devoted much of his effort in the last 10 years to understanding at an atomistic level the growth of metallic nanostructures, and has shown how, in particular, steps mediate the growth …,” says Lagally. “Professor Huang has taken these concepts one step further here to demonstrate how the existence of steps can be used to control the size of nanorods, in particular how to make them extremely thin. The work is fascinating and rests on sound theoretical principles.”

The research team’s primary goal was to define the scientific framework behind metallic nanorod growth and show, theoretically, how very thin nanorods could be grown. Actually growing clearly separated nanorods 10 nanometers in diameter was an added reward – and one they almost missed.

One of the quirks of working with nanorods at the level of 10 nanometers in diameter is you can hardly see them under most microscopes. Also, when the gold nanorods cited in the study were first made, they looked green. When Stagon placed the material under a scanning electron microscope to get a better view, at first all he saw was a field of grey.

“It is really testing the resolution limit of any scanning electron microscope,” Stagon says. “Fortunately, the microscope at UConn’s Center for Clean Energy Engineering is among the best.”

Stagon says the experience has taught him to fully appreciate the benefits of basic engineering science and how crucial it is to furthering technology and industry. His long-term goal is to be a professor so he can pass on the importance of core science to other budding engineers.

Niu says the project is “the most important and exciting work” he’s ever done.

“There are a lot of derivations in mathematics,” says Niu, who was recently promoted to assistant research professor. “When you finally find the equation, when you look at it and it is so simple and beautiful, and then you do simulations and the results mirror the equation, I cannot describe how happy that makes you feel.”

Huang says Stagon’s and Niu’s success reflects the commitment of UConn and its senior faculty to recruit and support top-notch graduate students and post-doctoral researchers. Federal officials have recognized the strength of UConn’s graduate programs by issuing 13 GAANN grants to UConn graduate students over the past seven years.

“We pay a lot of attention to our graduate education and postdoctoral students,” Huang adds. “Not only are we successful in attracting extremely talented American and international students, we also are very successful in retaining them through prestigious fellowships and other supports. They are critical to both our research success and our university mission, because after all we are an educational institution and our mission is to provide an environment for the next generation of engineers and prepare them for their future careers.”