The University’s drug development research capabilities received a substantial boost with the recent opening of two new research facilities at the Biotechnology-Bioservices Center.

The new high-throughput screening and microcalorimetry facilities are supported by advanced instrumentation that will allow University scientists and researchers across multiple disciplines to perform important tasks more efficiently and at reduced cost.

The facilities place UConn on par with other top pharmaceutical research institutions across the country. “This is another example of how the University of Connecticut is supporting not only its own research priorities, but also those of private industry and manufacturing within the state,” says David F. Grant, director of the Biotechnology-Bioservices Center and an associate professor of toxicology in the Department of Pharmaceutical Sciences. “This equipment provides state-of-the-art equipment and technologies otherwise prohibitively expensive for individual research laboratories.”

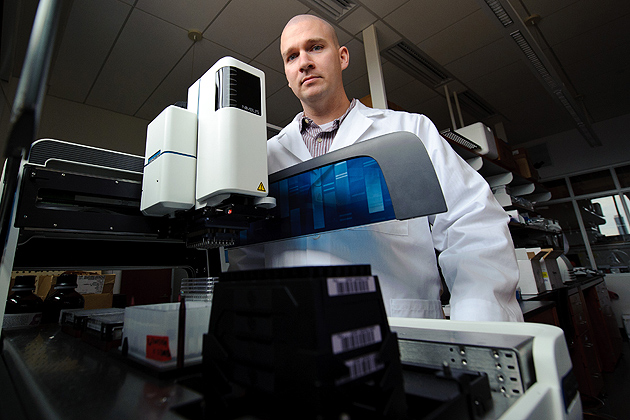

“In the past, a researcher might have gone to outside entities to run certain tests and that can be expensive,” says M. Kyle Hadden, an assistant professor of medicinal chemistry in the Department of Pharmaceutical Sciences. Hadden manages the High-Throughput Screening Facility with Dennis Wright, an associate professor of medicinal chemistry in the School of Pharmacy.

“Now that we have this equipment in-house, that same researcher can come to us and we can perform the test for them at a much lower cost,” says Hadden. “The downstream effect of all this, we hope, will be more collaborative projects that bring in more funding and advance research. A lot of federal government funding right now is going toward more collaborative research that goes across disciplines and ultimately produces stronger research.”

High-throughput screening has become an integral tool in the identification of new lead compounds that might ultimately become drugs. UConn’s high-throughput screening facility includes a benchtop liquid handler that automates specimen preparation and an integrated multi-mode microplate reader and stacker that can run assays on thousands of compounds to see which ones are most suitable for an individual’s research goal, such as suppressing a certain protein that contributes to a disease. In other words, the high-tech instruments help pharmaceutical scientists separate favorable new drug compounds from the duds. Compounds identified by academic researchers as being potentially effective can then be used and tested by private industry as potential drugs.

The new equipment for both facilities was acquired through the University’s competitive major equipment investment program. In addition, the high-throughput screening facility also acquired a library of 150,000 compounds for use in testing. In the past, researchers had to purchase such compounds from outside vendors. UConn’s compound bank is believed to be one of the largest, and possibly the largest, of any academic institution in the state.

“It’s a huge thing to have this many compounds on the UConn campus,” Hadden said.

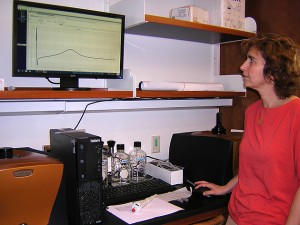

The microcalorimetry facility is supported by two key pieces of equipment – a nano-isothermal titration instrument and a nano-differential scanning instrument. These two instruments help researchers better understand the thermodynamic profiles, stability and binding affinity of different molecules in solution.

The stability and binding strength of a ligand to its receptor are very important if we want to use the molecule as an effective drug, says Olga Vinogradova, an associate professor of medicinal chemistry and the microcalorimetry facility’s director. The more stable the compound under investigation is and the stronger its interaction with the target, the more potential it has to become an effective drug.

The instruments in the microcalorimetry facility are extremely sensitive and use significantly smaller quantities of the samples during testing, which allows researchers to receive more reliable data, more efficiently at a lower cost, Vinogradova says.

“These are state-of-the-art instruments that require only a very small volume of sample, only about 200-300 microliters, and that is important because very often the material we use is very, very limited,” says Vinogradova. “In other labs with older machines, we might use volumes seven times higher and testing those samples is more expensive and more time consuming.”

Like the instruments in the high-throughput screening facility, those in the microcalorimetry facility help researchers screen out potentially viable compounds from those that won’t work. In a way, the two facilities work in tandem with the microcalorimetry lab serving as the next step in the screening process for the favorable compounds identified in Hadden’s lab.

The two new facilities, located in the Pharmacy/Biology Building off North Eagleville Road, complement the existing instrumentation already available in the Biotechnology –Bioservices Center. The center also contains instruments for analytical ultracentrifugation, bioinformatics, DNA biotechnology, flow cytometry, mass spectrometry, nanofabrication, nuclear magnetic resonance, and protein x-ray crystallography.

Besides the pharmaceutical sciences, other disciplines that will benefit from the two new facilities include chemistry, molecular and cell biology, neurobiology, materials science and biophysics.