As the aviation industry strives to achieve net zero CO2 emissions by 2050, engineers at the University of Connecticut are designing a sustainable jet propulsion system with the ambitious goal of being cleared for take-off within the next three decades.

While most aircraft rely on jet fuel to power a flight, the combustion of this fossil fuel releases greenhouses gases into the atmosphere, contributing to climate change and the depletion of finite oil resources. Using sustainable aviation fuels (SAF) is a viable option, but some scientists, like those at UConn, are exploring newer technologies such as using fuel cells for hybrid propulsion.

“This is an amazing time to see humans starting to transition from using internal combustion engines to electrics; kind of like when we moved from wood to coal and coal to oil,” says David L. Daggett, a scholar affiliated with UConn’s Center for Clean Energy Engineering (C2E2).

“This is an amazing time to see humans starting to transition from using internal combustion engines to electrics; kind of like when we moved from wood to coal and coal to oil,” says David L. Daggett, C2E2 Scholar

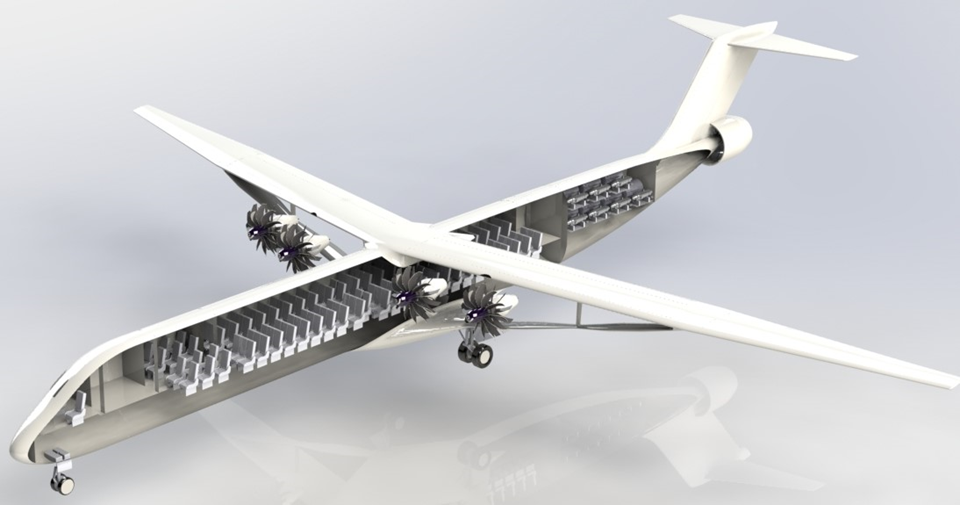

A UConn team and fellow research partners are designing a carbon-neutral energy storage and power generation system that could serve as an alternative for aircraft propulsion.

The proposed system will consist of optimally sized fuel-to-electric power conversion devices (fuel cells and turbogenerators) using carbon-neutral SAF. Batteries will provide additional electrical power to the aircraft during the power-hungry climb phase of a flight and be recharged during descent.

Senior Design engineering students are currently building a small-scale airplane to demonstrate the concept.

The project, titled “High Performance Metal-Supported Solid Oxide Fuel Cell (SOFC) System for Range Extension of Commercial Aviation” is supported by a $4.5M cooperative agreement from the U.S. Department of Energy Office of Advanced Research Projects Agency – Energy (ARPA-E) under its Range Extenders for Electric Aviation with Low Carbon and High Efficiency (REEACH) Program. This grant will support Phase II of the project over a two-year period.

“We are thrilled that ARPA-E is continuing to support this project as we’ve already made significant progress,” says Xiao-Dong Zhou, the Nicholas E. Madonna Chair in Sustainability, Connecticut Clean Energy Fund Professor of Sustainable Energy, director of C2E2, and professor of chemical and biomolecular engineering, materials science and engineering, and mechanical engineering at UConn.

“The DOE ARPA-E program is immensely competitive and has been highly lauded by the National Academies, academia and industry to push the technology to market,” says Subhash Singhal, a member of the National Academy of Engineering (NAE), and Battelle Fellow Emeritus at the Pacific Northwest National Laboratory.

Phase I of the project began in August 2020 when the U.S. Department of Energy first awarded $33 million in funding to 17 projects as part of the ARPA-E REEACH program. Zhou, who worked at the University of Louisiana at Lafayette at the time, received $2,263,000 in funding to develop a concept that uses innovative fabrication techniques for high-performance, ultra-low weight, and low-cost solid oxide fuel stacks. Fuel cell stacks generate electricity through an electrochemical process, rather than combustion.

Phase I study showed that SOFCs and batteries have now progressed enough to consider fuel cells to power future long-range commercial airplanes with no harmful emissions or performance degradation. Unlike traditional batteries, which store energy and must be periodically recharged, fuel cells can continuously generate electricity if the SAF or renewable liquid natural gas and an oxidizer (air) are continuously supplied.

For Phase II, the team of researchers will refine their initial airplane design and fuel cell integration concepts to make them easier to commercialize.

“You have to consider that very high development costs result in commercial airplane designs that are typically produced for 50-some years,” Daggett says. “Incorporating some changes now will enable that future airplane to possibly morph into an all-electric airplane within its likely 50-year design life.”

In this UConn study, the team is using solid oxide fuel cells, which operate at high temperatures, as opposed to proton exchange membrane (PEM) fuel cells that operate at lower temperatures. SOFCs can use a turbine downstream to recover high quality heat energy.

“This results in more efficient utilization of the fuel than today’s low temperature PEM fuel cells as well as future turbine engines,” Scott Swartz, chief technology officer and co-founder of Nexceris, explains.

Other members of the C2E2 research team at UConn include Wilson Chiu, professor of mechanical engineering; Yudong Wang, assistant research professor of mechanical engineering; Stoyan Bliznakov, associate research professor; and Nengneng Xu, assistant research professor.

Once the designs are finalized, Nexceris will work to manufacture and commercialize the SOFC stack technology. UConn and Nexceris have had discussions with potential SOFC-based aviation system integrators, such as Boeing, General Electric, Rolls-Royce, Pratt & Whitney, and others, to secure licensing arrangements.

“This project, led by Professor Zhou and his outstanding team, will benefit UConn’s research innovation efforts while contributing to carbon neutrality,” says UConn President Radenka Maric, Connecticut Clean Energy Fund Professor of Sustainable Energy in the departments of chemical and biomolecular engineering and materials science and engineering. “Building a more sustainable future for our university, our nation, and the world is the great challenge of our lifetime. UConn must always be at the forefront of that effort.”