A new experiment led by biomedical engineering researchers at the University of Connecticut is taking place 254-miles off Earth— inside the National Aeronautics and Space Administration’s International Space Station.

Connecting ISS astronauts to Storrs via videoconferencing is no easy feat, but a team of School of Engineering researchers made it happen this spring to facilitate experiments featuring life-saving nanomaterials.

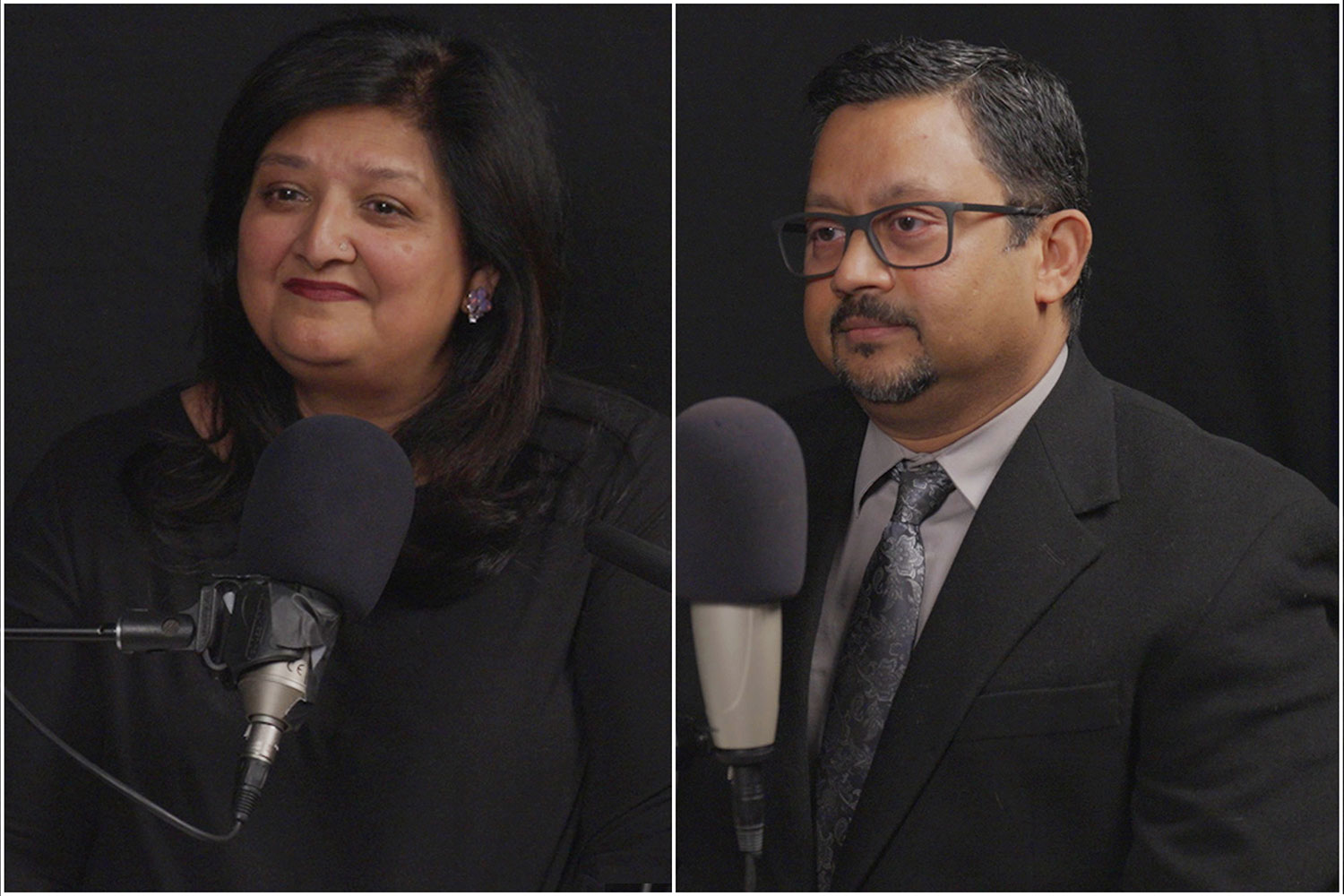

Biomedical Engineering Associate Professor Yupeng Chen, who is the principal investigator of these experiments, and his graduate students partnered with UConn-affiliated Eascra Biotech and Axiom Space.

The teams are organizing a proof-of-concept study aboard the ISS involving the fabrication of Janus base nanomaterials (JBN), a family of novel biomaterials that mimic DNA.

Low-gravity experiments yield benefits across a wide range of health disciplines.

These biomaterials are potentially marketable and can be used in therapeutic and regenerative treatments for people with arthritis, cancer, and neurological diseases.

“The whole family of Janus base nanomaterials are all formed by self-assembly,” Chen says. “Self-assembly is different from when we traditionally manufacture materials. We don’t have full control. So we can only influence the self-assembly process by altering the environment. And of course, with microgravity, there’s no forces and the materials can assemble much better into their structures.”

Chen’s students all have various research interests.

For example, Ph.D. candidate Maxwell Landolina ’22 (ENG) is specifically looking at a Janus base nanomatrix that is used to regenerate human cartilage.

Chen and his students used videoconferencing to communicate with ISS in late May from the Engineering and Science Building (EBS). Other graduate students on this project include Anne Yau ’24 (BME), Ian Sands, Jin Zhai, Wuxia Zhang, Trystin Cote, Jinhyung Lee, Sidharth Masarur, Leah Faber, and Olivia Rice. Several undergraduate students are also assisting Chen and Landolina.

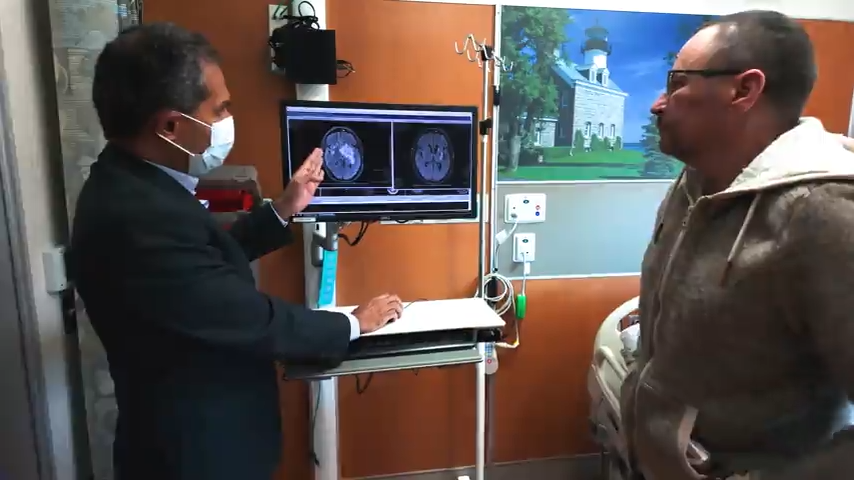

The UConn team used the relatively simple VLC Media Player and Microsoft Teams software to connect with the ISS in real time. Chen and Landolina instructed the two astronauts through the experiments.

Astronauts were well-prepped for the live videochat, having received careful instructions from the UConn researchers in the days preceding the call. Only a few small interjections from the Storrs crew were necessary, like when Landolina asked the ISS team to carefully scrape the samples from the sides of the test tubes to properly mix the materials.

The space team kept all the samples carefully contained in a large box, but they still had to keep an eye on the samples as they bumped and nudged each other in the absence of gravity.

One of the main challenges with coordinating the videocall was scheduling. Astronauts operate on an extremely tight schedule, working in 15-minute increments on other experiments, research, outreach, and media engagements.

In fact, the ISS moves at an incredibly high speed, orbiting the Earth every 90 minutes. This means the crew experiences 16 sunrises and sunsets every 24 hours.

“This is not my first space project, but it’s really interesting to see how all this comes together,” Yau says. “It’s a cool process, I’m really glad that I’m in this mission.”

Landolina seconded Yau’s comment, and says that because he wants to eventually work in the regenerative medicine industry, he has appreciated seeing these public and private partnerships working together.

The Axiom Space team completed the experiments perfectly, Chen says. After the nine-day, 3,867,500-mile journey, the astronauts carefully packed the assembled nanomaterials and testing equipment, sending them back to Earth aboard the SpaceX Dragon Freedom spacecraft. On May 30 at 11:04 p.m. EDT, both the crew and the experimental materials safely splashed down off the coast of Florida.

Presently, the Chen lab is conducting a series of comprehensive tests on the nanomaterials fabricated in space.

Two additional missions through UConn, NASA, Axiom Space and Eascra Biotech are planned over the next 24 months are planned.

The long-term goal for Axiom Space and Eascra Biotech is to create a permanent “manufacturing” facility for therapeutic biomaterials in space.

“Axiom Space plans to attach its first module to the ISS in late 2025,” says Chen, who is also a cofounder for Eascra Biotech. “They provided support for the precursor mission to ensure success in future NASA InSPA funded missions. In missions two and three we will scale up the production of JBN and transfer the experiments to their station.”

Nanomaterials are ultrafine particles of matter, usually between 1 and 100 nanometers (nm) in diameter. A nanometer is roughly one millionth of a millimeter, or about 100,000 times smaller than the diameter of a human hair. Materials engineered to such small scale can take on unique optical, magnetic, electrical and other properties with tremendous potential impact in the fields of electronics, medicine and beyond. Apply these materials in a low or no-gravity situation and the results can have profound impacts on the medical industry.

The $1.86 million contract through UConn, Eascra Biotech, and Axiom Space is one of only eight winning proposals submitted in response to NASA seeking space production applications for low-Earth orbit missions.